Remember that I broke a spoke on my old HED Ardennes rear wheel? I happen to have spare spokes, because I have taken those wheels on trips and you never know if you can find a replacement far from home.

I took the wheel to a bike shop to be repaired. I got it back in a couple of days. But before I put the tire and cassette back on the wheel I decided to try an experiment.

Mark Stemmy , owner of OCS, was going to pick up my Zipp wheels for a re-optimization. He last worked on them something like 10 years ago. He agreed to take a look at the freshly shop-trued HED wheel at the same time.

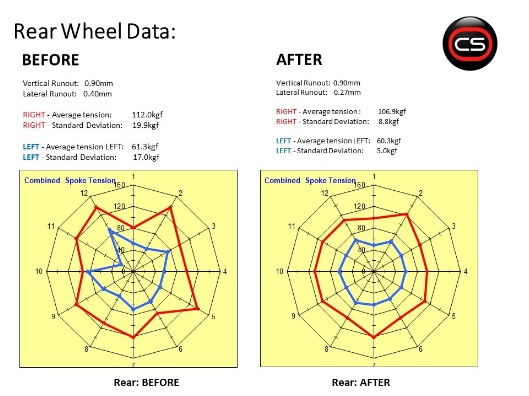

I didn’t quite know what to expect, but here is the result:

The left picture shows the spoke tension when the wheel came back from the shop. The right picture shows spoke tension after Mark adjusted them. The standard deviation went from 19.9 kgf to 8.8 kgf on the drive side (R) and from 17.0 kgf to 5.0 kgf on the non-drive side (L).

I’m not criticizing anyone here. I don’t really know how important it is for a wheel to have even spoke tension. But I do know that I want MY wheels to have even spoke tension.

Servicing a wheel the way OCS does it takes time and costs money. At least double what a shop charges. It is worth it to me to know that the person working on my equipment really wants to do it right, the way I would if I had the skill and tools. I have neither, which is why I’m glad OCS exists.

You definitely have skills and tools cousin but if you’re like me, most of the time, they’re not the ones you need…hahaha.

LikeLike

OCD? Call OCS.

LikeLike

Well SPOKEN article!

LikeLike